Evans Metal Products, Inc. recently announced the addition of advanced, on-site scanning capabilities using Trimble X7 3D scanning technology and software on a wide range of portfolio projects throughout the Midwest. Company president David Evans explained, “We’re now able to provide our customers with highly accurate, on-site measurements with practical application in building construction, facilities management, and industrial survey applications. All these are aided by Trimble 3D scanning technology.” Founded in 1978, Trimble’s technology solutions are used in over 150 countries with Trimble employees in more than 40 countries.

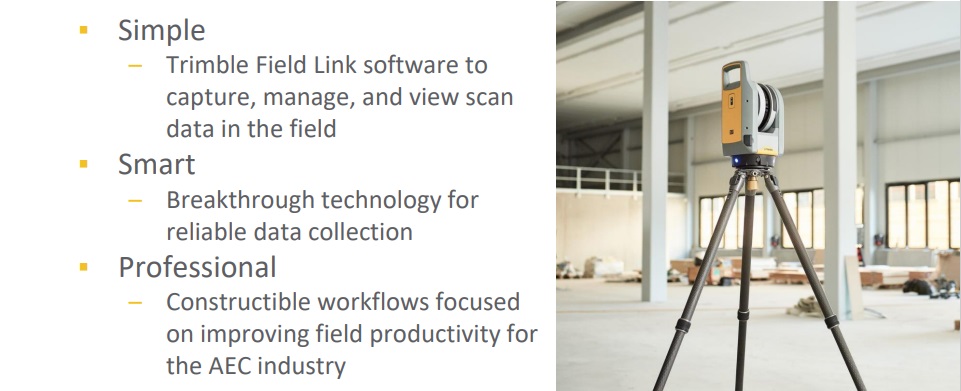

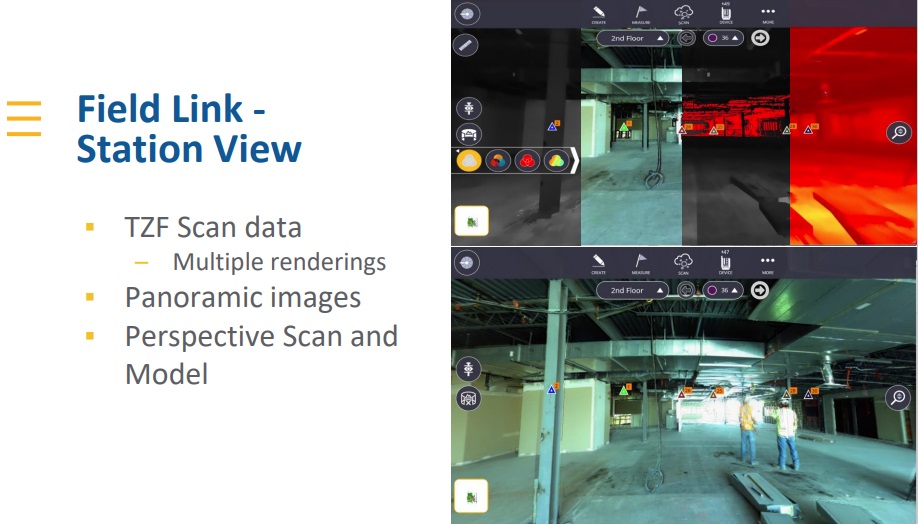

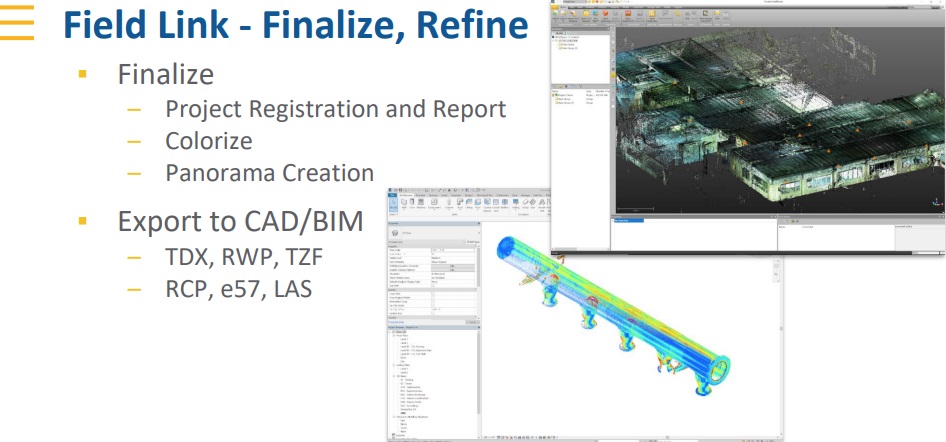

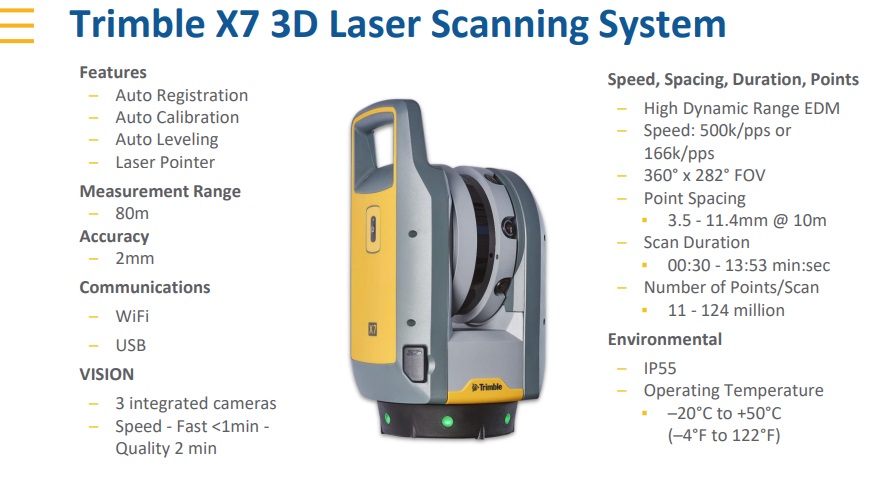

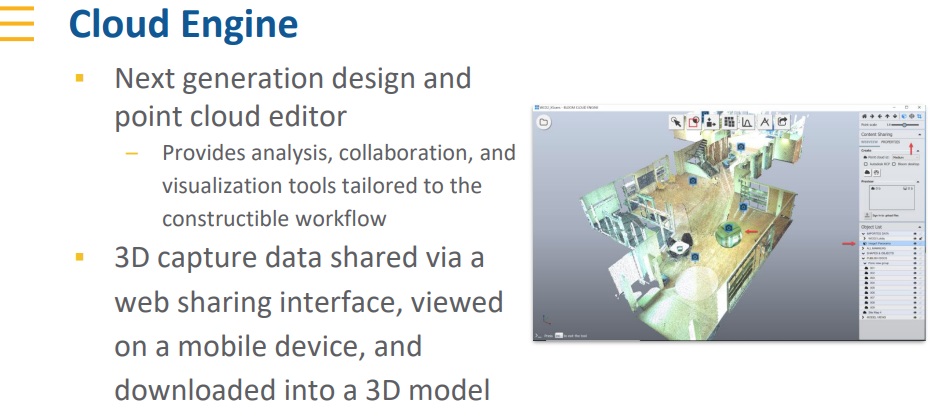

Evans continued, “After careful evaluation, we selected Trimble’s X7 technology because of its combination of simplicity of operation, breakthrough technology for reliable data collection and constructable workflows focused on improving field productivity. The application possibilities for 3D scanning are nearly endless. For example, the interior of a very large venue can be scanned and rendered with incredible levels of detail. Recent scans have provided accuracy to the nearest eighth inch. This gives our firm the unique capability to reduce planning time and drive projects costs lower for our clients.

Scanning Service Applications

Here are a few of the many applications Evans Metal is now offering clients.

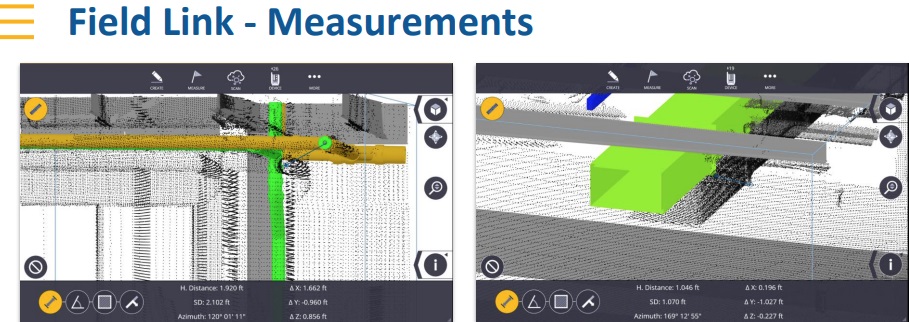

• Floor flatness reports

• Accurate as-built data

• Scanning of walls, ceilings before they are enclosed for as-built documentation.

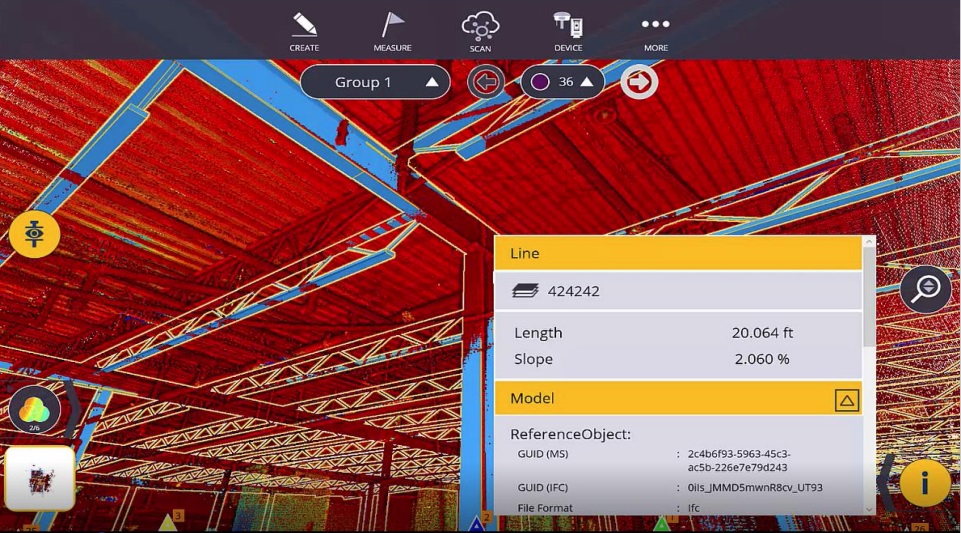

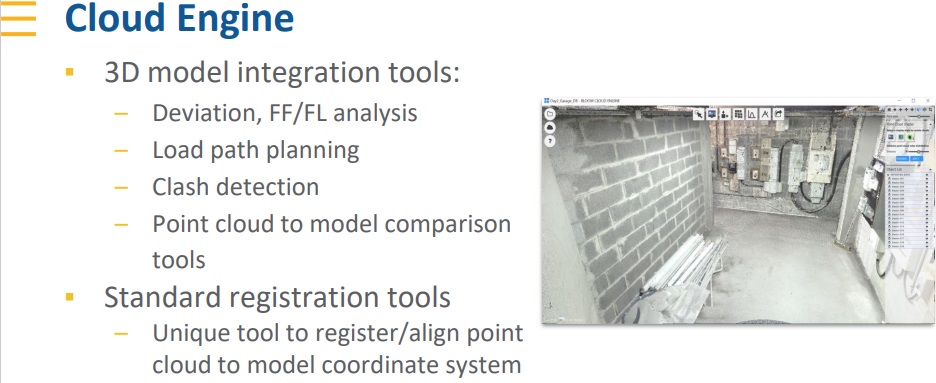

• Collaborating with BIM models

• Deflection reports

• QA and QC scanning during construction

• Accurate dimensions with line of site up to 80 meters (260′)

• Serving architects, designers, engineers, plant managers, mechanical contractors, & construction companies.

URL / 3-d-laser-scanning

Evans Metal Products continues to be a leading innovator metal fabrication through use of state-of-the-art technologies such as Trimble® X7 3D Laser Scanner technology. Advanced 3-D Laser Scanning serves to substantially improve the accuracy of measurements and calculation accuracy, accelerated project milestone schedules and reduced customer costs.

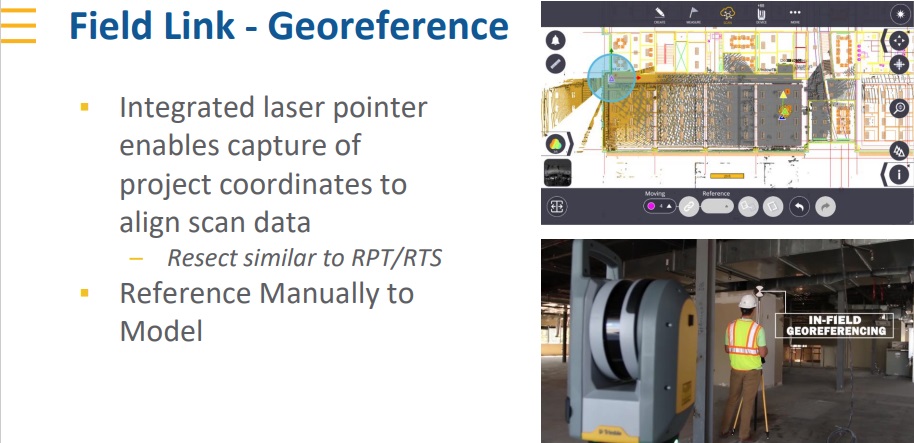

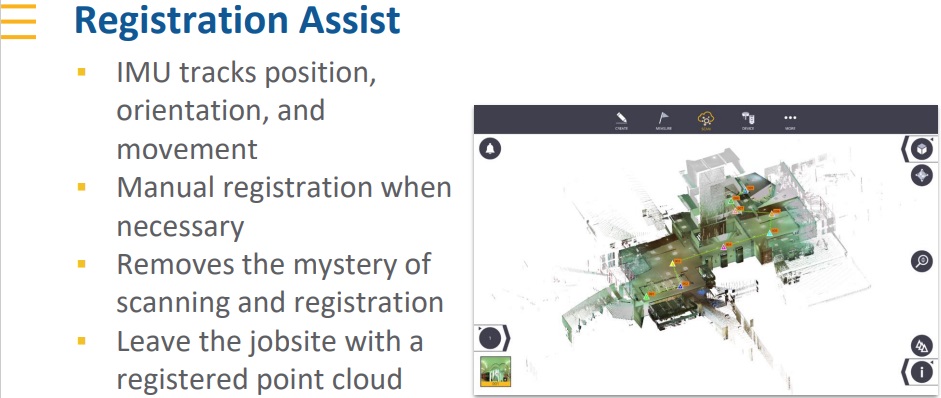

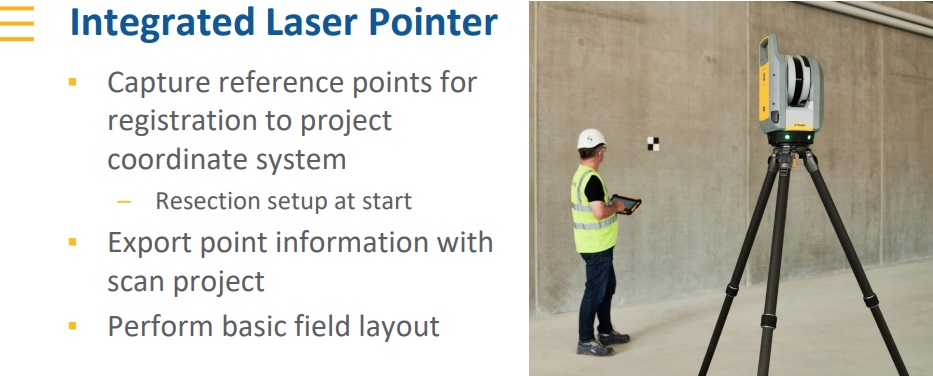

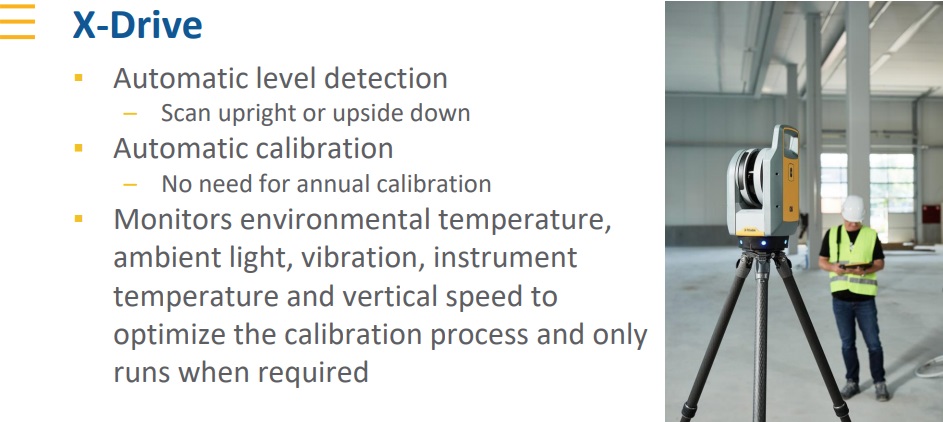

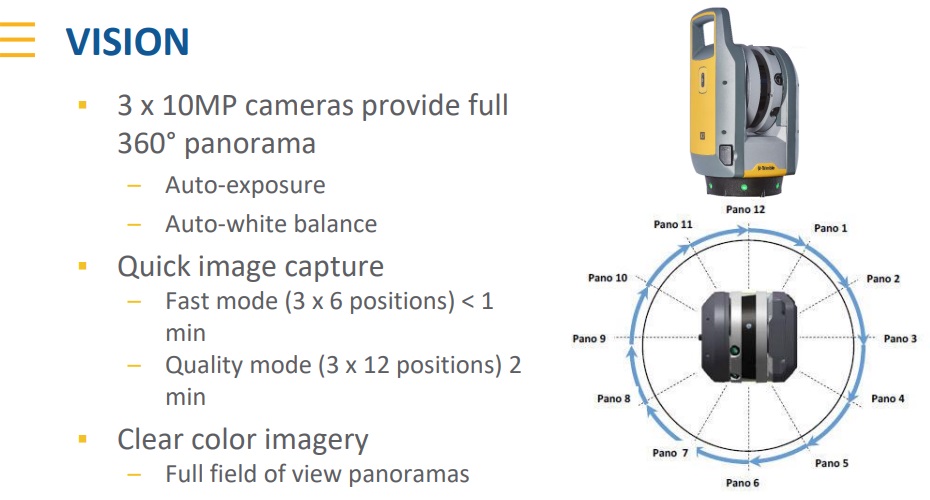

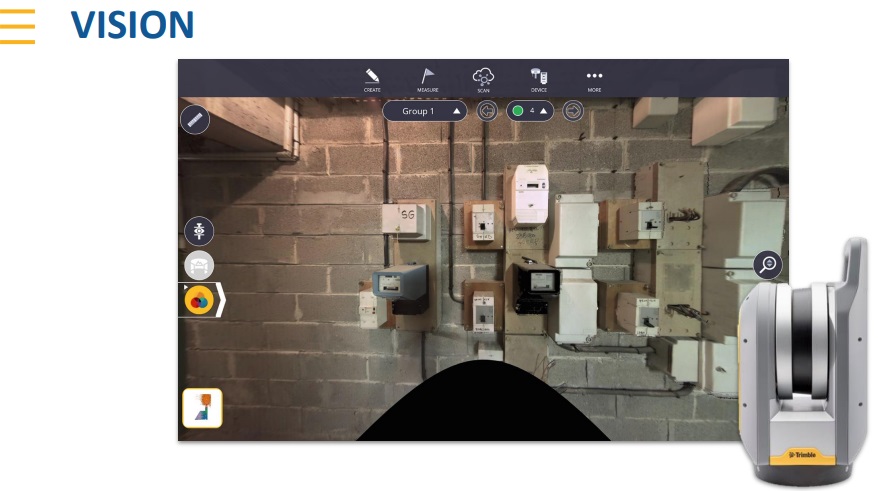

Our high-speed 3D laser scanning systems delivers powerful performance benefits for our clients with feature sets that includes smart automatic calibration systems where no targets or user interaction required, self-leveling automatic survey grade level compensation, laser pointing that confirms individual reference points, georeferencing scans, complete with on-demand calibration reports which have almost endless use applications.

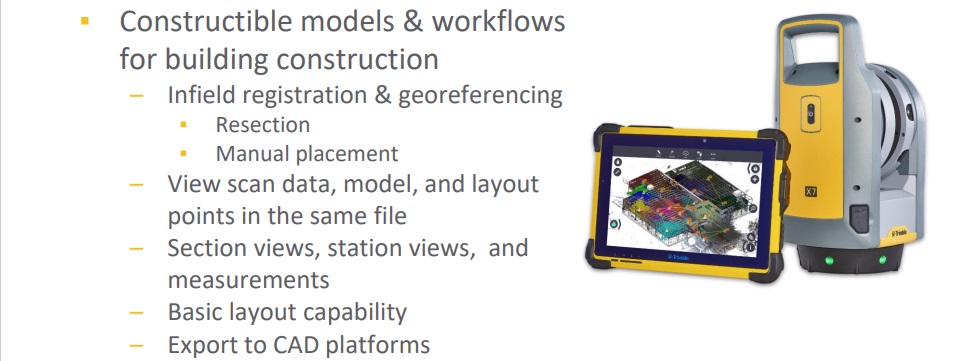

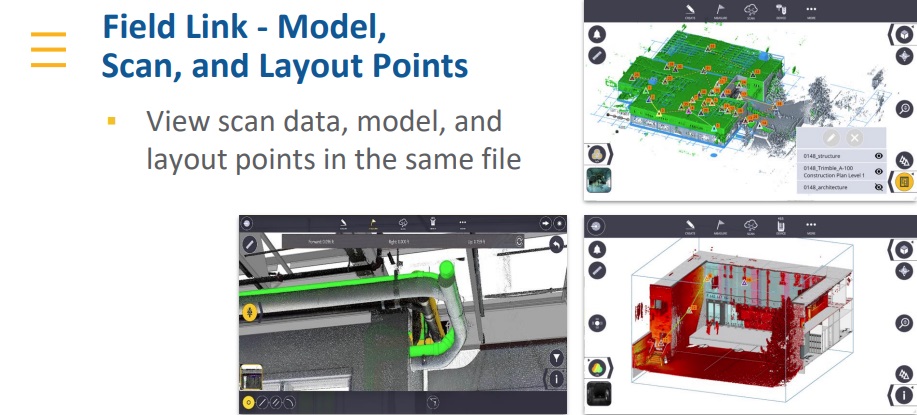

Building Construction/Facility Management

The Trimble® system is safe and effective to provide services to the buildings market, to create as-built models for scan to BIM and for renovations. Provide utility for building extensions, conversions and inspection of facades and elevations. Handle design optimization and accessibility planning. Use survey-grade self-leveling to verify verticality, floor flatness and to analyze deformation of beams and columns. In-field registration verifies the entire project has been captured to eliminate the risk of return visits, especially where access permits are difficult to obtain. Use the laser pointer for single point measurements and geo-referencing.

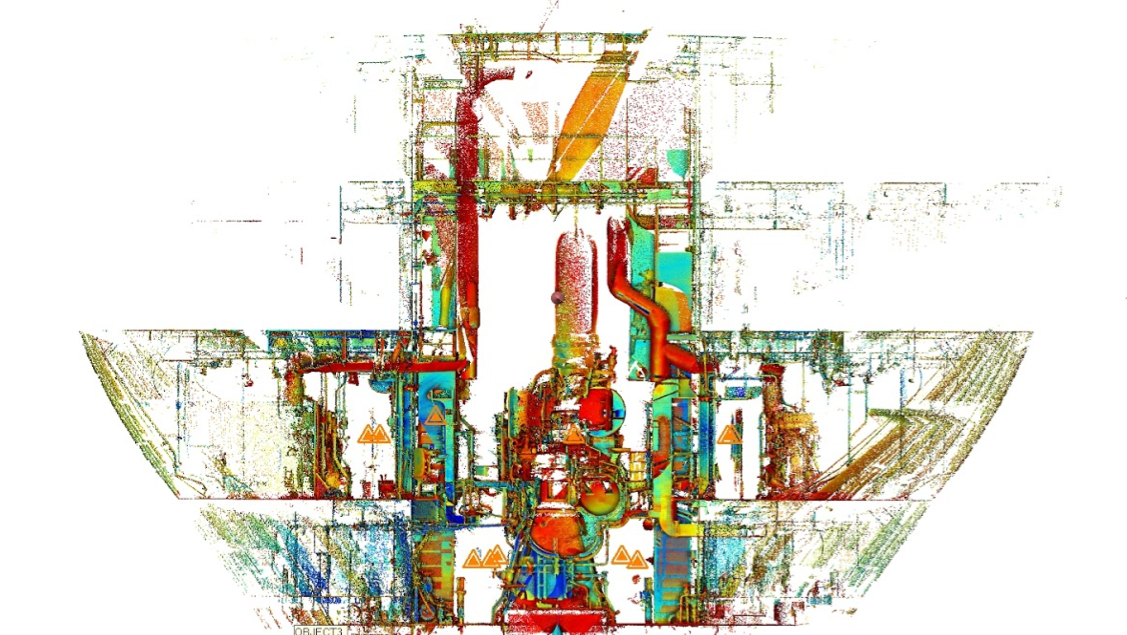

Industrial Survey

Create as-builts of industrial facilities for CAD modeling, plant revamp design, interference detection and verification of fabricated components. The Trimble® system high sensitivity scan mode ensures highly precise data capture in complex environments where black and highly reflective metals are present. The compact, lightweight design and custom backpack make it easy to transport and climb ladders to access elevated platforms. In-field registration confirms the area has been captured entirely, eliminating costly field rework for critical projects when plants are shut down. Use the laser pointer for geo-referencing to a plant coordinate system to match scans perfectly with CAD design models. Target Based Registration can also use survey control and targets scanned by the X7 to automatically register the scans for export to plant design CAD software.

Civil Infrastructure

Create as-built documentation for drawings or models for bridges, tunnels, dams, etc. Use scan information in clearance calculations, modeling, inspections, renovations, and expansion work. High-speed data capture reduces downtime for critical infrastructure projects. The compact, lightweight design makes it easy to transport and set up in a variety of environments. In-field registration allows users to verify that the scan data has been captured in its entirety, before returning to the office, reducing downtime and eliminating the need for multiple site visits. Use the laser pointer to geo-reference scans to project coordinate systems.

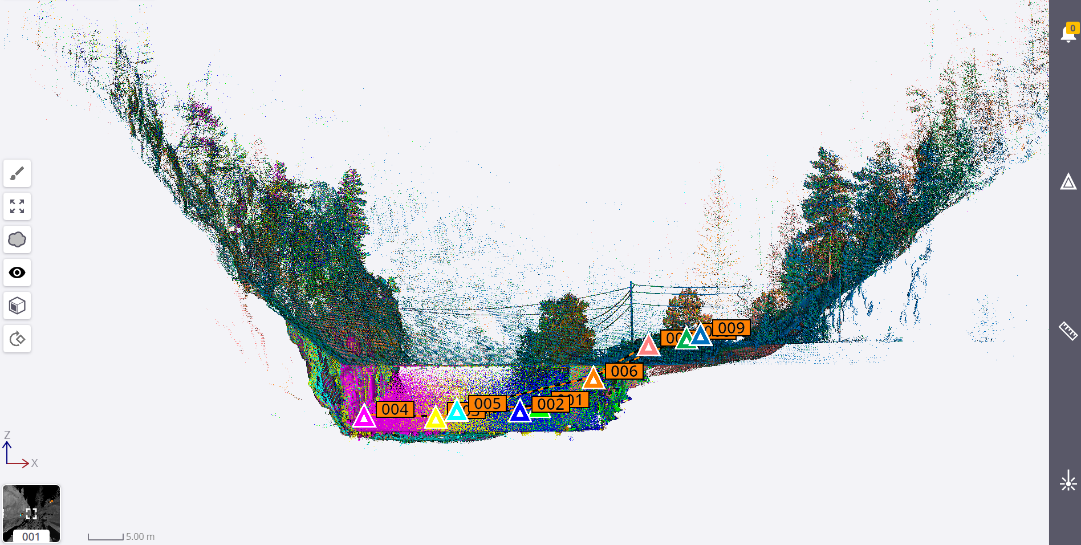

Topographic/General Surveys

Capture features for land title surveys, including property boundaries, buildings, easements, site improvements, right-of-ways, encroaching elements, and complex structures. Assign labels to create scan groups and simplify the display of specific areas and add annotations with pictures to document items of interest. You can also use the laser pointer to geo-reference scans to project coordinate systems. Capture millions of data points in a fraction of the time it would take to capture significant features using traditional topographic survey methods. The Trimble® system’s compact, lightweight design make it easy to transport and set up, no matter the environment.

Road Intersection Surveys

Create as-builts of road corridors, intersections, roadway surfaces, lane striping, flow-lines, manholes, right of way monuments, and overhead power lines. High-speed data capture from a safe distance reduces the need for lane or road closures. In-field registration allows for immediate verification that the entire survey area has been collected, eliminating return visits and additional permit costs. Use the laser pointer to geo-reference scans to project coordinate systems.

Forensics

Quickly capture information at crime scenes and vehicular accidents. Minimize road closures with high-speed scanning and imaging, even on dark vehicles and roadways, and in extreme weather conditions. Add annotations with pictures to points of interest and take measurements in the field. The compact, lightweight design enables easy transport and setup when space is limited. In-field registration verifies complete data capture before leaving the scene. Export data is used in the creation of 2D/3D diagrams and animations for investigation and reconstruction. User the laser pointer to geo-reference scans to project coordinate systems.

Utilities

Conduct general surveys for water, sewer, gas, power substations, powerlines, telecommunications, and cell towers. High-speed data capture reduces downtime for critical projects and in-field registration verifies the required data has been captures for inspections, clearance calculations and repairs.

Marine Construction

Create as-builts for new construction, renovation, and optimization. The compact, lightweight design and custom backpack make it easy to transport and set up in congested areas. The auto-calibration function ensures accuracy in volatile environments. The system can automatically address temperature swings and vibration to ensure the best possible accuracy and will notify the user if excessive movement is detected.

Tank Calibration & Inspection

Efficiently capture precise details of storage tanks and surrounding containment areas. The survey grade self-leveling will ensure you can accurately verify verticality and the compact and lightweight design will make entry and setup inside tanks easy. Quickly capture and verify the data in the field for import for module analysis. Calculate tank volume filling tables and secondary containment volumes. Perform deformation analysis for tank repairs and create reports meeting API 653 standards.

Mining

Scan underground mines and quarries for deformation monitoring and stockpile volume calculations. Use the High Sensitivity scan mode to precisely capture both dark and bright materials. The X7’s compact, lightweight design and custom backpack make transport and setup easy, even in underground mines. High-speed scanning will reduce downtime and the IP55 rating will provide reliable operation in tough, dusty environments. We can import data directly for comprehensive analysis

Contact Form:

Cultural Heritage

Historic preservation projects require great detail to inspect or monitor surface deterioration. The Trimble® system has the range, accuracy, resolution and imagery required to deliver. Quickly capture cultural heritage landmarks and add annotations with images to further document the site. The Trimble® system is easy to transport to remote locations and the in-field registration ensures you can validate the data before you leave. Help plan restoration efforts or simply capture history.

High-Speed 3D Laser Technology Improves Field Scanning Capabilities

Evans Metal Products adds Trimble 3D tech for faster, more accurate scanning in building construction, and industrial applications increasing accuracy of survey applications

Elkhart, IN; Evans Metal Products , Inc. today announced the addition of advanced, on-site scanning capabilities using Trimble X7 3D scanning technology and software on a wide range of portfolio projects throughout the Midwest. Company president David Evans explained, “We’re now able to provide our customers with highly accurate, on-site measurements with practical application in building construction, facilities management, and industrial survey applications. All these are aided by Trimble 3D scanning technology.” Founded in 1978, Trimble's technology solutions are used in over 150 countries with Trimble employees in more than 40 countries.

Evans continued, “After careful evaluation, we selected Trimble’s X7 technology because of its combination of simplicity of operation, breakthrough technology for reliable data collection and constructable workflows focused on improving field productivity. The application possibilities for 3D scanning are nearly endless. By example, the interior of a very large venue can be scanned and rendered with incredible levels of detail. Recent scans have provided accuracy to the nearest eighth inch. This gives our firm the unique capability to reduce planning time and drive projects costs lower for our clients.”

Scanning Service Applications

Here are a few of the many applications Evans Metal is now offering clients.

Floor flatness reports

Accurate as-built data

Scanning of walls, ceilings before they are encloses for as-built documentation.

Collaborating with BIM models

Deflection reports

QA and QC scanning during construction

Accurate dimensions with line of site up to 80 meters (260')

Serving architects, designers, engineers, plant managers, mechanical contractors, & construction companies

About Evans Metal Products, Inc.

Established in 1945 and located in Elkhart, IN, Evans Metal Products designs and fabricates a wide variety of metal products along with installation services for both commercial and residential clients. Evans Metal has provided structural steel for over 77 years fabricating a wide variety of structural steel components and also miscellaneous fabrications such as ladders, rails, canopies and stairs, including wrought iron and ornamental products. Evans Metal is able to fabricate all sorts of products including hand rail using steel, stainless steel, aluminum, and bronze. While most of our products say in the Mid-west, we produce and ship material all over the

The company also provides custom fabrication specializing in welding, cutting, shearing, bending and finishing, offering their expertise and proficiency to meet a wide variety of fabricating needs. Other areas of specialization includes high precision plasma cutting services, weldments in steel, aluminum and stainless steel including “passivization” of stainless steel parts, manufacture of repetitive parts and products weighing less than 10,000 lbs each. Pipe bending in multiple planes using mandrel and non-mandrel bending machinery assures clients with accurate and repetitive parts. The company also offers circumferential as well as longitudinal finishing of stainless steel and aluminum. Evans Metal Products is an AISC & AWS Certified Fabricator and is a proud member of NOMMA. For details and career opportunities visit www.evansmetal.com.